Heat Resistant Casting

AstroMet-the leader in manufacturing of masking compound for Gas Carburising / Gas Nitriding and Indian Partners of M/s.Durferrit GmbH (Formerly Degussa AG), Germany for heat treatment salts and additives, have now added one more feather in the cap – manufacturing of high Ni/Cr alloy steel castings.

Using ultra-modern induction melting facility, AstroMet manufactures range of high Ni/Cr alloy steel castings conforming to ASTM A-297 grades HH, HK, HN, HT, HU etc.. Apart from these alloys, high Ni/Cr alloys as per customers’ specification are also offered.

AstroMet is already catering to range of engineering industries including automobile, bearing, fasteners, petrochemicals, chemicals, pharmaceuticals, food and allied industries.

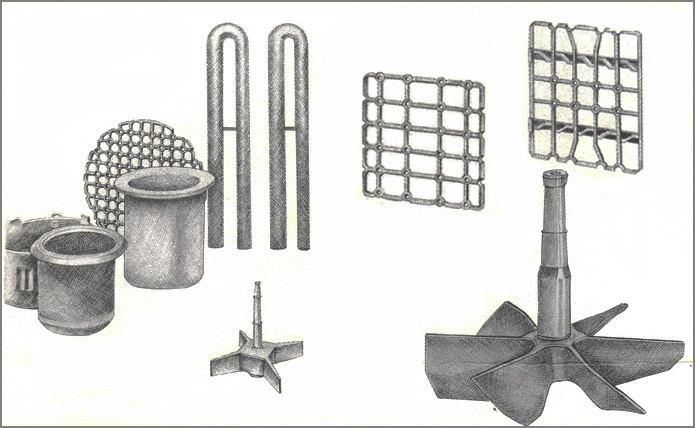

Range of castings manufactured include heat resistant casting such as Trays, Fixtures, Impellers, Grids, Rails & Rollers, baskets, Hearth Plates etc.. The list is long.

When we produce a product, we sell you a value. Our castings are manufactured using methods, standards and techniques that ensure they are worth when measured for their usefulness. We stand behind every product we make. Astromet has what you need.

Typical Composiion of Heat Resistant alloy Casting

ALLOY CASTING GRADE |

NEAREST

IS-4522 GRADE |

ALLOY TYPE |

NEAREST AISI TYPE |

TYPICAL CHEMICAL COMPOSITION |

Ni% |

Cr% |

C% |

HD |

4 |

28 Cr 6 Ni |

327 |

4-7 |

26-30 |

0.5 max |

HH |

7 |

25 Cr 12 Ni |

309 |

11-14 |

24-28 |

0.2 - 0.5 |

HK |

9 |

25 Cr 20 Ni |

310 |

18-22 |

24-28 |

0.2 - 0.6 |

HN |

11 |

20 Cr 25 Ni |

- |

23-27 |

19-23 |

0.2 - 0.6 |

HT |

12 |

35 Ni 15 Cr |

330 |

33-37 |

13-17 |

0.35-0.75 |

HU |

13 |

39 Ni 19 Cr |

330 |

37-41 |

17-21 |

0.35-0.75 |

HX |

14 |

66 Ni 17 Cr |

- |

64-68 |

15-19 |

0.35-0.75 |

TYPICAL USE OF HEAT RESISTANT CASTING

| ALLOY HK :- |

This alloy is one of the most economical combination of strength and stability above 900 C. It is used for parts such as gas carburising, furnace parts and chains. Other uses include brazing fixtures, cement kiln nose segments, retorts, radiant tubes etc. |

| ALLOY HN :- |

This alloy can be satisfactorily used in several specialized applications including forging baskets, brazing fixtures etc. It can also be used for furnace beams, radiant tubes, tube supports, nozzles & trays for polymer / water quenching applications

|

| ALLOY HT :- |

Most widely used alloy in resisting thermal shocks of heating and cooling and is resistant at high temperature to oxidation / carburization up to 1000C. This alloy is widely uses for load bearing members in many furnace application. Typical uses include Radiant Tubes,Furnace Pots, Hearth Plates, Charge Trays etc. |

| ALLOY HU :- |

This alloy has exceptionally high combination of creep strength and ductility up to 1100C It has good resistance to corrosion in oxidizing or reducing atmospheres containing moderate sulphur. Typical uses include gas dissociation equipments, salt pots, quenching trays / fixtures. |

| ALLOY HX :- |

High alloy content of this grade confers high resistance to hot gas corrosion even in presence of some solphur. It is mostly used where maximum and widely fluctuating temperatures are expected.Typical uses are for quenching fixtures, burner parts, carburising or cyaniding equipments etc. |

|